Hotmelt Coating & Laminating Machine

Hotmelt Coating & Laminating Machine

Hotmelt Coating and Lamination is a futuristic and sustainable technology to produce premium quality functional textiles. This technology does not subject the substrates to any kind of thermal stresses and offers flexibility to work with any subsrate combinations (Textiles / Foam /Film / Membranes / Nonwovens etc) to meet even the most challenging functional demands.

We offer below mentioned Hotmelt Adhesive Application methods:

- Gravure Roller

- Multi Roller

- Slot Die

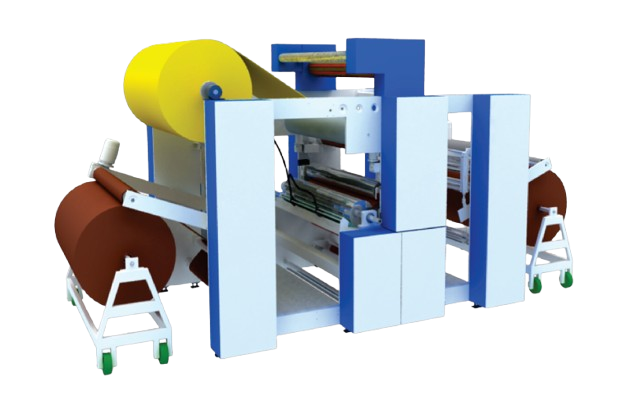

Hotmelt Coating & Lamination machine to manufacture Self Adhesive Tapes by Transfer Coating Method

Self Adhesive tapes can be manufactured by direct as well as transfer coating technique using Hotmelt Slot Die coating method. The machine shown above is used to manufacture Self Adhesive Tapes which find applications in Meditech, Buildtech, Shoe industry and

various other industries as well. The beauty of the machine lies in its capability to handle the complicated process in single pass with

ease.

The First coating station has a reverse roll / gravure roll to coat back side of Fabric with a special chemical that prevents the Hotmelt glue from sticking to other surface after rewinding. Vertical Heating with IR heaters is provided to ensure effective drying of the fabric.

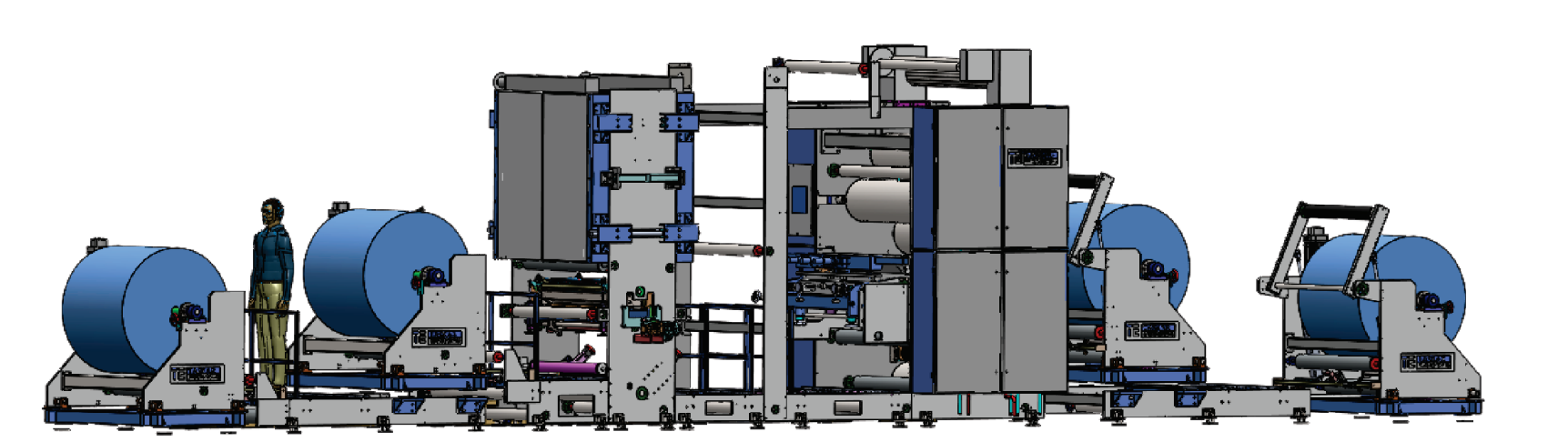

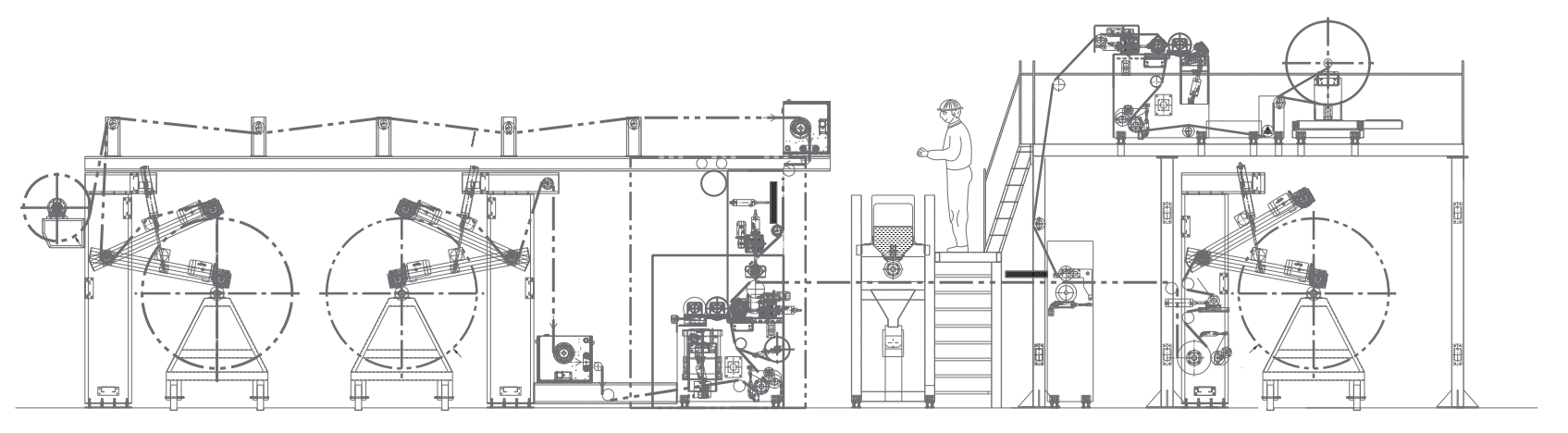

Multi purpose Hotmelt Coating & Lamination machine for 3 layer lamination with Scattering unit to produce Fabrics for NBC Suits

The above layout shows a multipurpose Hotmelt Coating and Lamination Machine to manufacture three layer laminated textiles in one

pass. Few substrates/processes may require preheating before coating hotmelt glues. In the above machine, it is possible to customized the IR heating to cater to such specialised requirements as well.

Since, the machine produces three layered laminates in single pass, it completely eliminates the fabric handling hassles that happen in

dual pass machines. Hence, it not only saves a lot of process time but also opens up new avenues with increased production capacity.

Scatter coating unit can also be supplied in case of special application demands.

Specs & Features

- Working Width: 300 – 4000 mm

- Gravure Application system GSM range: 3 – 40

- Multi Roller Application System GSM range: 10 – 500

- Slot Die Application System GSM Range

- Compact Machine Design

- Extremely precise Pressure Rollers with electronic micron gap settings

- Uniform Heating across the width of Application rollers / Doctor Blade

- Heating Medium: Thermic Oil

- Unwinding and Rewinding system with accurate tension control

- Guiding devices to ensure perfect alignment of substrates during lamination

Application